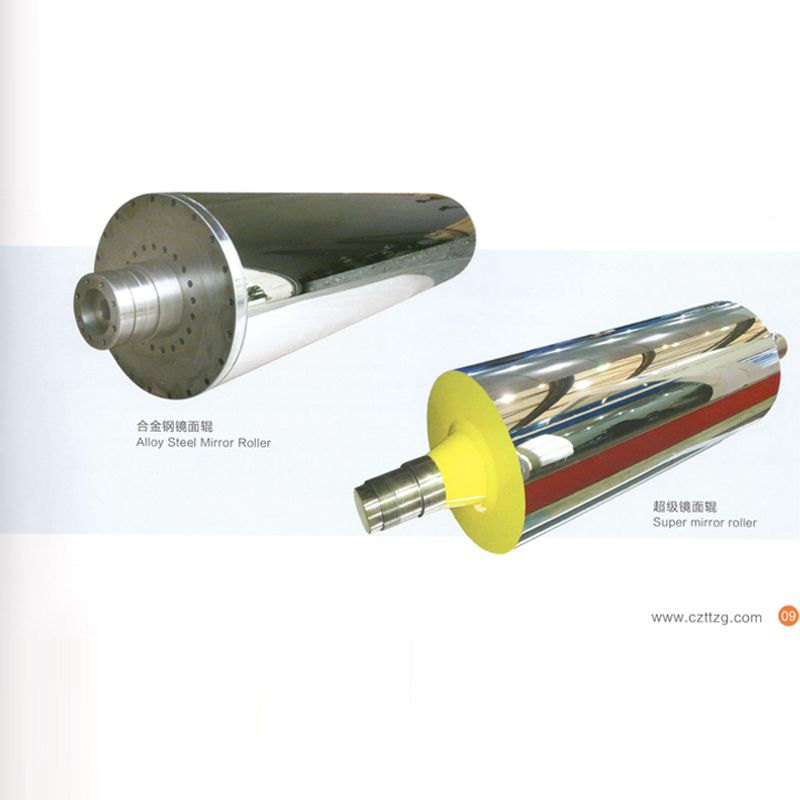

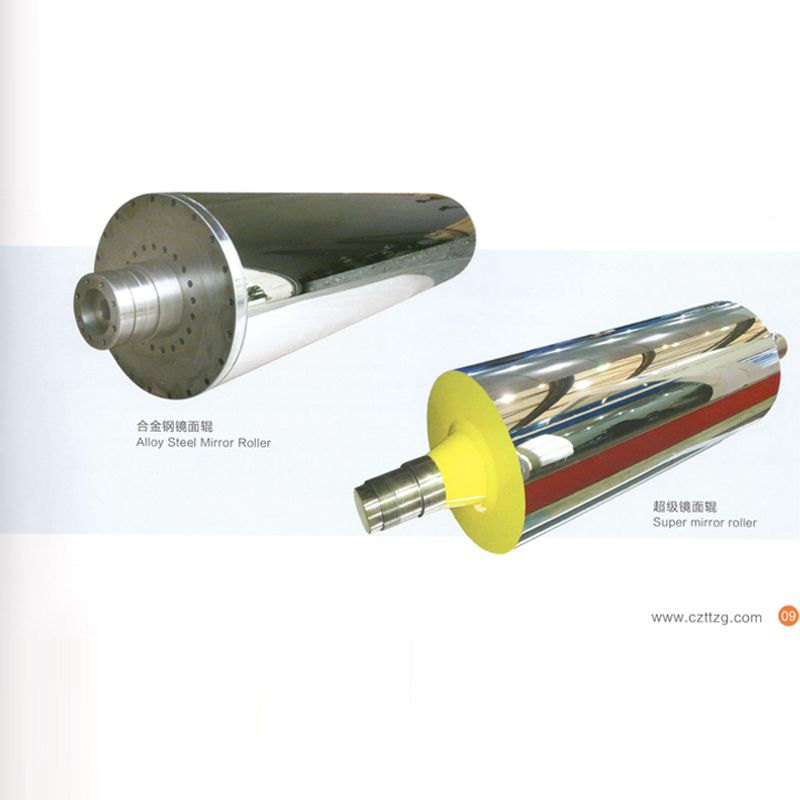

Каток для зеркала

We specialize in the production of various types of mirror rollers. Mirror roll is an indispensable part in the plastic industry, including plastic products such as sheets, plates, and films. Widely used in extrusion, calendering, casting equipment. Calendering treatment on the surface of plastics (PVC, ABS, PP, PE, PET, PC, etc.), leather, paper, textiles, etc.

Features

▪ The material is made of No. 45 seamless steel roll or alloy steel through welding, stress relief, tem-pering, quenching and other mechanical processing.

▪ The flow channel inside the roller is reasonable, and the temperature difference of the roller surface is ±1 degree Celsius.

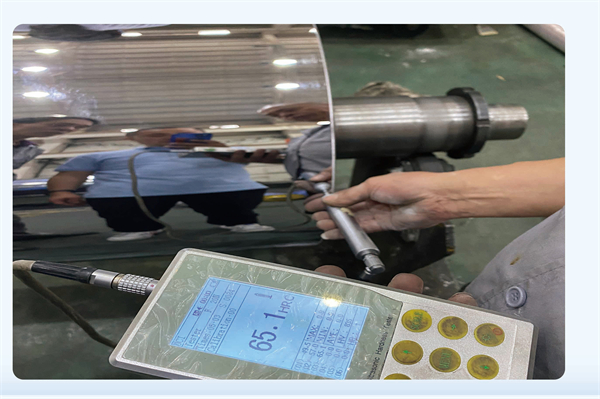

▪ The outer tube of the roller is subjected to intermediate frequency quenching and normalizing treat-menấThd the surface hardness of the roller body reaches 55HRC

▪ The thickness of the chroming layer is made according to the customer's needs. Generally, the thick-ness of the electroplating layer is 100u, and the hardness reaches 60HRC after hard chrome plating.The roughness of the mirror roller reaches Ra 0.01, and the concentricity is less than 0.01mm.

Manufacturing Process

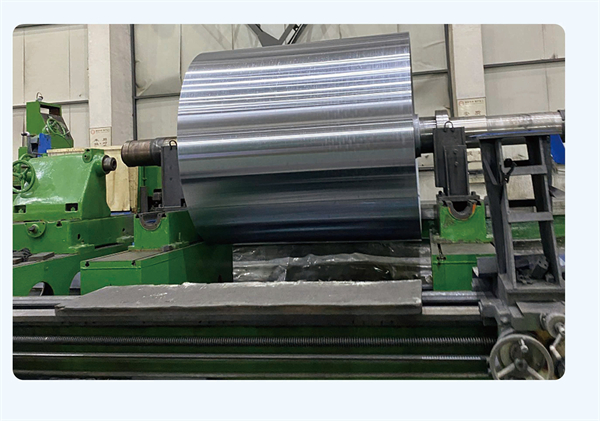

Roller base Machining

Internal Structure

Shrink Fitting

Grinding

Mirror Finish

Скачать фокус

Телефон:+86 15135905492

WhatsApp/WeChat:+86 15135905492

Добавить:Шаньси Юньчэн, Китай